What is Tempered Glass? A Brief History

Tempered glass has revolutionized safety standards since the early 1900s. Originally developed for automotive windshields, this innovative safety glass quickly expanded into construction, electronics, and architectural applications.

The tempering process involves heating glass to approximately 650°F (343°C) and then rapidly cooling it through controlled air jets. This creates surface compression that makes the glass 5 times stronger than regular glass while ensuring it breaks into small, safe pieces rather than dangerous shards.

Today, tempered glass applications range from smartphone screens to skyscraper windows, making it an essential material in modern construction and technology.

Professional Tempered Glass Manufacturing in Montreal

Les Produits Verriers International (IGP) specializes in custom tempered glass manufacturing using advanced thermal tempering technology. Our state-of-the-art facility produces CSA-certified safety glass for residential, commercial, and architectural projects throughout the Greater Montreal area.

Heat-Strengthened vs. Fully Tempered Glass

Our heat treatment process offers two strength levels: heat-strengthened glass (2x stronger than regular glass) and fully tempered glass (5x stronger). Both treatments enhance thermal resistance and impact strength while meeting strict Canadian building codes for safety glazing applications.

5 Key Advantages of Custom Tempered Glass

Superior Safety

When broken, tempered glass fragments into small, rounded pieces that are much safer than sharp shards, significantly reducing injury risk in homes and businesses.

Exceptional Strength

Our tempered glass withstands up to 5 times more force than standard glass, making it ideal for high-traffic areas and challenging applications.

Thermal Resistance

Excellent resistance to temperature changes up to 200°C, perfect for fireplace doors, facades, and Quebec’s climate variations.

Long-Term Durability

Superior scratch resistance and structural integrity ensure your investment lasts longer with minimal maintenance requirements.

Enhanced Security

Increased break-in resistance makes tempered glass an excellent choice for doors, windows, and security-sensitive applications.

Tempered Glass Applications & Solutions

Our custom-cut tempered glass serves diverse applications: shower enclosures, glass railings, partition walls, tabletops, fireplace doors, and architectural panels. Each piece is precision-cut to your exact specifications with beveled or polished edges for safety and aesthetics.

Beyond tempered glass, we offer laminated glass, annealed glass, and specialty glazing solutions with over 2,500 hardware pieces available for complete project support.

Why Choose IGP for Your Tempered Glass Needs?

With decades of experience serving Montreal, Laval, Longueuil, and the South Shore, Les Produits Verriers International combines advanced manufacturing technology with personalized service. Our technical consultants ensure every project meets your exact specifications while adhering to Canadian safety standards.

Ready for your custom tempered glass project? Contact our experts today for professional guidance, competitive pricing, and fast delivery throughout the Greater Montreal area.

Frequently Asked Questions

Tempered Glass Manufacturer in Montreal | Les Produits Verriers International

Are you a tempered glass manufacturer or installer?

What is tempered glass and why choose it?

What types of glass do you manufacture?

What’s the difference between tempered and laminated glass?

Do you supply hardware with glass?

What thicknesses of tempered glass do you manufacture?

Can tempered glass be cut or drilled after manufacturing?

What are your manufacturing lead times?

Is tempered glass resistant to temperature variations?

Do you work with contractors and architects?

Do you offer specialty glass (anti-reflective, tinted, frosted)?

What safety certifications do your tempered glass products meet?

Have a Specific Question?

Contact our experts for personalized advice on your tempered glass projects

TEMPERED OR HEAT-STRENGTHENED GLASS

The most common type of safety glass is tempered glass, which is made by heating pre-cut panels of glass to about 650 C (1200 F), then cooling them rapidly through a process called ‘quenching.’

By cooling the outer surfaces of the panel more quickly than the center, quenching puts the surfaces and edges of the glass in compression and the center of the glass in tension.

In addition to making tempered glass four to five times stronger than conventional annealed glass, reheating and rapid quenching dramatically changes the break characteristics of the glass.

Broken Tempered Glass

shattered into thousands of tiny pebbles.

THAT’S WHY WE HAVE TO DO

THE QUALITY CONTROL

Fragmentation testing is required to determine that the glass product meets the minimum breakage particle requirements as specified for thermally toughened glass.

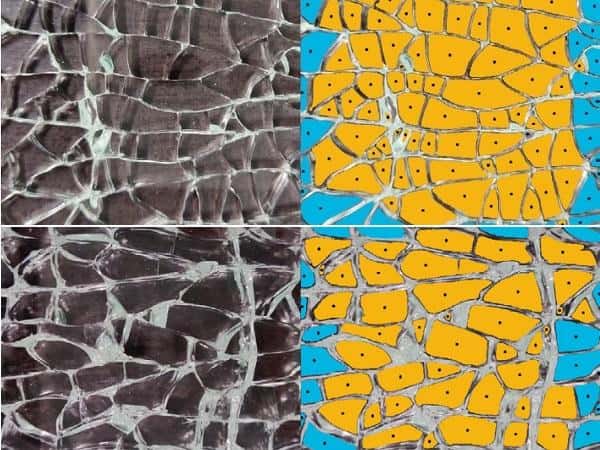

Fragmentation Counting

The fragment count in the standardized fragmentation test

The destructive test and the fragmentation due to breakage is the way to define the stress and safety level of the tempered glass. The fragmentation shows several things from the stresses, e.g. the stress level and the uniformity of the stresses.

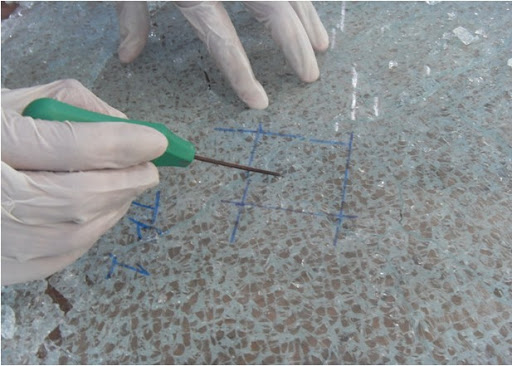

Manual Fragmentation Analysis

Fragmentation analysis is a proven way to confirm the safety level of glass. In essence, when thermally strengthened glass fractures into smaller pieces, it is less dangerous. Depending on the glass thickness, several standards define the minimum number of fragments required for safety.

- Fragment counting should occur between 3 to 5 minutes after fracturing the glass. This is important because after a longer period of time, secondary cracks start to form.

- The counting area should be 50 x 50 mm, ± 1 mm.

- The chosen counting area should have the least number of fragments.

- All particles wholly contained within the area should be counted as one fragment.

- Particles which are partially within the area should be counted as 1/2 a fragment.

Manual counting

Area of 50 x 50 mm, ± 1 mm.

The tempered glass fragmentation test gives good insight into the quality of the tempering process.