WHAT IT IS?

Insulated glass units (IGUs) were developed and introduced into the overseas commercial and residential window markets in the 1930s. IGUs (often referred to as double glazed units) are a combination of two or more panes of glass spaced apart with a spacer bar. The glass panes are then hermetically sealed to form a single unit with one or more air spaces in between. Heat transfer by radiation, conduction and convection is reduced by the extra glass and air barrier that an IGU offers over single glazing. The correctly specified IGU will improve thermal performance which will reduce heating and cooling costs of the dwelling.

Glass panes in an IGU are separated by a ‘spacer’. Spacers can be found in a number of commercially available materials, each of which has an effect on the performance of the IGU.

Simply contact our team today for further information or to request a callback.

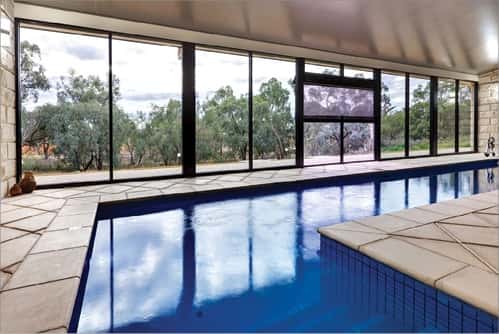

EFFENCIENCY & STYLE

SOME HISTORY

Before 1992 most of the spacers were made of aluminum. This material is a great conductor of heat and cold. In summer time it gets hot and increases the chances of seal failure of the window. In winter time it gets cold, making the edges of the window glass colder. That reduces the energy efficiency of the replacement window.

In 1992 IGP glass introduced Intercept Warm Edge Spacer. Intercept features one piece U-shaped alloy, that reduces conducted heat loss. U-shaped system is flexible and does not allow for seal failure.

With warm edge intercept spacer your window is going to expand in summer time and contract in winter. No condensation is going to happen between the window panes as well.

ADVANTAGES

- Faster cooling or heating times, compared with single-pane alternatives.

- Enhanced indoor retention of cool air in summer, or warm air in winter, relieving strain on heating systems and air conditioners.

- More consistent internal temperatures, offering greater levels of comfort to building occupants.

- Reduced noise ingress.

- Improved asset saleability.

- Diminished energy loss due to unwanted draughts.

- At IGP GLASS we are qualified to assist specifiers with preferred configurations and specifications to achieve desired energy rating benchmarks. Variables such as glass selection and performance values, glazing treatments and styles, sizing, cavity spacings and materials are all addressed holistically to ensure completed fittings are compliant with all relevant Canadian standards and building codes.

Insulated Glass by IGP Glass:

Advantages, Trends, and Why You Should Choose It

Insulated glass has become increasingly popular in the construction industry due to its energy efficiency and aesthetic appeal. As a result, many glass manufacturers have started offering their own versions of insulated glass. In this blog post, we will discuss the advantages of insulated glass, the current trends in the market, and why you should choose IGP Glass for your next project.

Advantages of Insulated Glass

Insulated glass, also known as double-glazed or triple-glazed glass, consists of two or three glass panes that are separated by a spacer and sealed to create a vacuum or a gas-filled space between them. This design offers several advantages:

Better Energy Efficiency

Insulated glass provides better thermal insulation than single-pane glass. The space between the glass panes acts as a barrier to reduce heat transfer through conduction and convection. This means that less heat will escape from your building during the winter, and less heat will enter during the summer. As a result, you can save on heating and cooling costs and reduce your carbon footprint.

Reduced Noise Pollution

The air or gas-filled space between the glass panes also acts as a sound barrier, reducing the amount of noise that enters or leaves your building. This is especially beneficial if you live in a noisy neighborhood or work in a busy area.

Improved Safety and Security

Insulated glass is stronger and more durable than single-pane glass. In the event of an accident or a break-in, the glass is less likely to shatter into dangerous shards. This can help prevent injuries and property damage.

Trends in Insulated Glass

As the demand for energy-efficient and eco-friendly buildings grows, so does the demand for insulated glass. Here are some of the current trends in the market:

Smart Glass

Smart glass is a type of insulated glass that can change its transparency or color in response to external stimuli, such as light or heat. This technology can help regulate the amount of light and heat that enters your building and reduce your energy consumption.

Decorative Glass

Insulated glass does not have to be plain or boring. Many glass manufacturers offer a wide variety of decorative options, such as frosted, colored, textured, or printed glass. These options can add a unique and stylish touch to your building’s design.

Sustainable Glass

IGP Glass is committed to sustainability and offers several eco-friendly options, such as low-emissivity (low-e) coatings, recycled glass, and bio-based sealants. These options can help reduce your environmental impact and earn LEED points.

Why Choose IGP Glass?

IGP Glass is a leading manufacturer of insulated glass and has been in the industry for over 60 years. Here are some reasons why you should choose IGP Glass for your next project:

High Quality

IGP Glass uses the latest technology and the highest quality materials to produce insulated glass that meets or exceeds industry standards. All of their products undergo rigorous testing and quality control to ensure their performance and durability.

Customization

IGP Glass offers a wide range of customization options, including glass type, thickness, coating, spacer, gas, and color. They can also produce insulated glass in various shapes and sizes to fit your specific needs.

Expertise

IGP Glass has a team of experienced engineers and technicians who can provide technical support and assistance throughout the entire project, from design to installation. They can also help you choose the best insulated glass solution for your building’s requirements and budget.

Customer Service

IGP Glass is committed to providing excellent customer service and satisfaction. They offer fast and reliable delivery, competitive pricing, and responsive communication. They also have a customer portal where you can track your orders and access technical information and resources.

Conclusion

Insulated glass is a smart and stylish choice for modern buildings. It offers many advantages, such as energy efficiency, noise reduction, and safety, and is available in a wide variety of options, such as smart, decorative, and sustainable glass. If you are looking for a reliable and innovative manufacturer of insulated glass, consider IGP Glass. Their high quality, customization, expertise, and customer service make them a top choice in the industry.