Tempered glass has been used for various applications since its development in the early 1900s. Initially used for windshields in the automotive industry, it soon became popular in other sectors such as construction and electronics. Tempered glass is made by heating it to a high temperature and then rapidly cooling it, creating surface compression that makes it stronger and more durable than untreated glass. This process also makes it safer, as it breaks into small, rounded pieces rather than sharp shards. Today, tempered glass is used in many products such as smartphone screens and skyscraper windows due to its versatility and durability, making it an essential material in various industries.

About our Affordable wide variety of Tempered Glass solutions

Tempered glass, also referred to as toughened glass, is a safety glazing material commonly used in both residential and commercial settings. It is significantly harder than regular glass, achieved through a process called glass tempering. This process involves heating untreated glass to about 650 degrees Fahrenheit and then rapidly cooling it through compression in specialized equipment. As a result, tempered glass is less likely to break into large, dangerous shards, but instead breaks into small, pebble-like pieces that are safer to handle. The edges of tempered glass are also crucial to its safety, as they are the most susceptible to breakage.

Many Times Stronger

Glass is a versatile material that has been used in construction for thousands of years. Its unique properties make it an ideal choice for creating beautiful and functional structures. However, not all glass is created equal. When it comes to safety and durability, this type of glass is an excellent choice.

It’s used in buildings and homes where safety is a concern. This type of glass is created through a special tempering process that involves heating the glass to high temperatures and then cooling it rapidly. This process, known as “thermal tempering,” strengthens the glass and makes it much more resistant to breakage. Toughened glass is also known as “safety glass” because when it does break, it shatters into small, rounded pieces instead of sharp, jagged shards. Glass windows and walls must respect official safety building codes

What is heat Strengthen Custom Tempered Glass?

Tempered glass is a safety glass that has undergone a heat and chemical treatment to enhance its resistance and durability beyond that of standard glass. It is commonly used in situations where safety is a top priority, including car windows, shower doors, and tabletops. Compared to regular glass, it is highly resistant to thermal stress, shock, and impact. Additionally, when tempered glass breaks, it shatters into small, rounded pieces, reducing the risk of injury.

Advantages of Custom-Cut Tempered Glass

1. Custom tempered Glass Safety

This kind of glass is much safer and less dangerous than standard glass. Its resistance and durability make it much more resistant to breakage and impact, reducing the risk of injury. It’s also much less likely to shatter into sharp, dangerous pieces when it does break.

2. Toughened Glass Strength

Custom-cut tempered glass is much harder and stronger than standard glass. It has been treated with heat and chemicals to strengthen its structure, making it much more resistant to impact and breakage. It can withstand up to five times more force than standard glass, making it an ideal choice for applications where strength is a concern.

3. Thermal Resistance

Tempered glass is more resistant to thermal stress than regular glass. It can withstand higher temperatures without breaking or cracking, making it an ideal choice for applications where temperature changes are a concern. For example, it’s often used in fireplace doors because it can withstand the heat generated by the fire.

4. Durability

It’s more durable than standard glass. Its strength and resistance to destruction make it an ideal choice for applications where durability is a concern. It is also much less susceptible to scratches and other types of damage than regular glass.

5. Security

What makes tempered glass or toughened glass much more secure than normal glass? Its strength and resistance to destruction make it much more difficult for intruders to gain access to your home or business. It’s often recommended for use in doors and windows where security is a concern.

Why Choose IGP Glass Inc. for Your Custom-Cut Tempered Glass Needs?

IGP Glass Inc. is a reputable supplier of custom-cut tempered glass in Montreal, Canada, and the United States. With extensive experience in the glazing industry, we prioritize delivering high-quality products and exceptional service to our customers. Our team of experts is available to guide you in selecting the appropriate tempered glass for your specific needs and provide you with custom-cut glass that meets your precise specifications. Our product line extends beyond the tempered glass to include annealed glass, laminated glass, and more.

We offer a diverse selection of custom-cut tempered glass products such as fireplace doors, glass railings, glass partitions, glass doors, glass shower enclosures, glass tabletops, glass shelves, and other items to cater to your requirements.

Smart Tempered Glass Solutions and Applications

For custom-cut tempered glass in the Montreal area, reach out to IGP Glass Inc. Our team of experts is available to assist you in selecting the appropriate glass for your needs and provide you with custom-cut glass that meets your precise specifications. We prioritize delivering high-quality products and exceptional service to our customers. Contact us today to experience our commitment to your satisfaction.

FAQ

Q: What is tempered glass?

A: Tempered glass is a type of safety glass that is heat-treated to increase its strength. It is also known as toughened glass.

Q: What is the difference between tempered glass and regular glass?

A: Tempered glass is often used in applications where safety is a concern because if it does break, it will shatter into small, pebble-like pieces instead of large shards. Regular glass does not have this capability.

Q: What is the heat-treat process for tempered glass?

A: Tempered glass is made by heating the glass to a very high temperature, followed by a rapid cooling process. This creates compressive stress on the surface of the glass, while the interior remains under tension.

Q: What are the benefits of tempered glass?

A: Tempered glass is stronger than regular glass, making it safer for use in high-traffic areas or places where impact may occur. It also greatly reduces the risk of injury because, if it does break, it will shatter into small, pebble-like pieces instead of large shards.

Q: What are some common uses for tempered glass?

A: Tempered glass is often used in shower doors, windows, skylights, automotive glass, and furniture.

Q: Can tempered glass be cut?

A: Yes, tempered glass can be cut, but it must be cut before it is heat-treated because once it undergoes the heat-treat process, it cannot be cut without shattering.

Q: How is tempered glass tested for safety?

A: Tempered glass is tested by subjecting it to a series of impact tests, which simulate real-life situations. These tests ensure that the glass can withstand high levels of pressure and impact without breaking.

Q: How does tempered glass improve the safety of a building?

A: Tempered glass makes a building safer because it reduces the risk of injury in the event of breakage. Instead of large, dangerous shards of glass, it breaks into small, harmless pieces. This helps keep occupants safe and minimizes damage to the surrounding area.

Q: Is tempered glass more expensive than regular glass?

A: Yes, tempered glass is typically more expensive than regular glass because of the additional manufacturing process. However, the cost is often outweighed by the safety benefits.

Q: Can custom designs be added to tempered glass?

A: Yes, custom designs can be added to tempered glass during the manufacturing process. This allows for a dramatic look while still maintaining the safety benefits of tempered glass.

Contact us today to learn more about our Glass tempering process requirements and advantages

TEMPERED OR HEAT-STRENGTHENED GLASS

The most common type of safety glass is tempered glass, which is made by heating pre-cut panels of glass to about 650 C (1200 F), then cooling them rapidly through a process called ‘quenching.’

By cooling the outer surfaces of the panel more quickly than the center, quenching puts the surfaces and edges of the glass in compression and the center of the glass in tension.

In addition to making tempered glass four to five times stronger than conventional annealed glass, reheating and rapid quenching dramatically changes the break characteristics of the glass.

Broken Tempered Glass

shattered into thousands of tiny pebbles.

THAT’S WHY WE HAVE TO DO

THE QUALITY CONTROL

Fragmentation testing is required to determine that the glass product meets the minimum breakage particle requirements as specified for thermally toughened glass.

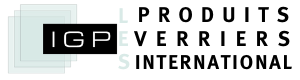

Fragmentation Counting

The fragment count in the standardized fragmentation test

The destructive test and the fragmentation due to breakage is the way to define the stress and safety level of the tempered glass. The fragmentation shows several things from the stresses, e.g. the stress level and the uniformity of the stresses.

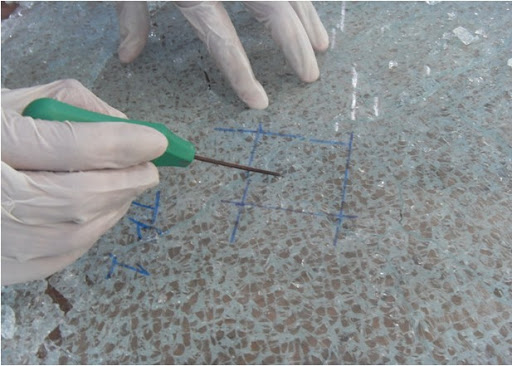

Manual Fragmentation Analysis

Fragmentation analysis is a proven way to confirm the safety level of glass. In essence, when thermally strengthened glass fractures into smaller pieces, it is less dangerous. Depending on the glass thickness, several standards define the minimum number of fragments required for safety.

- Fragment counting should occur between 3 to 5 minutes after fracturing the glass. This is important because after a longer period of time, secondary cracks start to form.

- The counting area should be 50 x 50 mm, ± 1 mm.

- The chosen counting area should have the least number of fragments.

- All particles wholly contained within the area should be counted as one fragment.

- Particles which are partially within the area should be counted as 1/2 a fragment.

Manual counting

Area of 50 x 50 mm, ± 1 mm.

The tempered glass fragmentation test gives good insight into the quality of the tempering process.